In Butterfly TEC, in addition to manufacturing table tennis blades and rubbers, research and development is also playing a crucial role. The research and development department produces numerous prototypes and conducts various evaluations, including lots of measurements, analyses, and tests by players. Through this repeated process over a long period, our equipment is developed. Here, we introduce several key research and development areas essential for the continuation of creating blades and rubbers that open up new horizons in the world of table tennis.

Shingo Usui Research and Development Department

“The advancement of equipment is indispensable for the development of sports. The direction of table tennis evolution may be determined by what kind of equipment we develop,” he says with a sense of mission and responsibility as he strives for unprecedented high performance in research and development.

Research and Development of Blades

To meet the demands of various players, daily research is conducted on the properties of wood and special materials, and how their combinations can result in different blade properties. For example, bending tests on wood and plywood are important indicators of blade performance, such as reaction and vibration properties, which are some of the evaluation criteria in blade development. Through continuous research and development, blades equipped with Cellulose Nanofiber (CNF) and Super ALC (Super Arylate Carbon) have been created recently. Additionally, not only have we been studying the physical properties of materials and plywood, but also the differences in blade and handle shapes and the influencing factors on bounce and hitting sensation.

Considering new product concepts based on players' needs.

Researching various combinations of wood and special materials.

Conducting bending tests on wood, testing their flexibility to verify the characteristics of the materials.

Repeatedly verifying hypotheses based on various data.

Research and Development of Rubbers

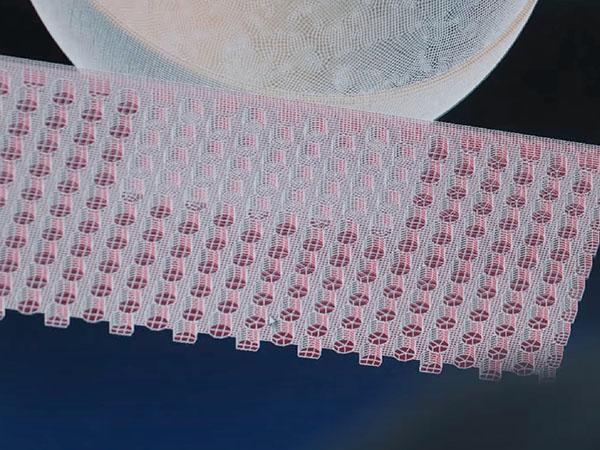

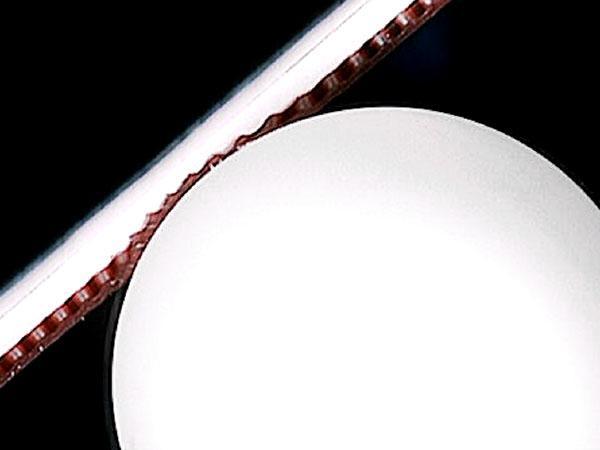

To develop products that exceed players' expectations, we conduct various research related to performance, such as the materials and the pimple shapes. Additionally, research on rubber quality is crucial to ensure stable product quality, not just performance. Therefore, we utilize numerous measurement devices, including microscopes and material testing machines, for evaluation. We conduct extensive verification on pimple shapes, sponge air bubbles and hardness, and sheet-sponge combinations, ultimately leading to product development. As a culmination of such research and development efforts, in 2019, we developed the Dignics series, which features the Spring Sponge X with enhanced elasticity compared to sponges before and a proprietary sheet compound with improved resistance to abrasion.

Preparing and evaluating rubber materials by combining various rubbers and chemicals.

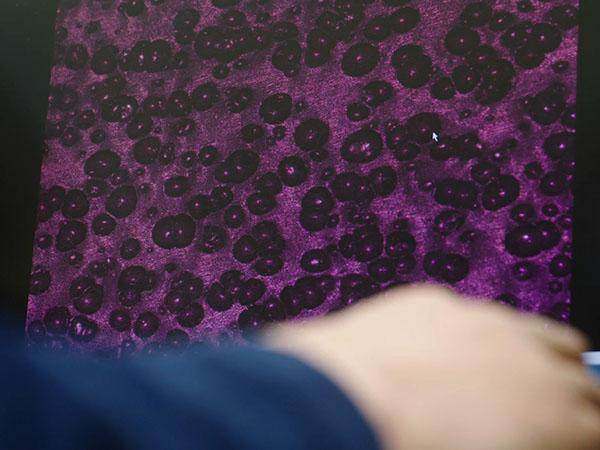

Measuring sponge air bubbles under a microscope to check their size and density.

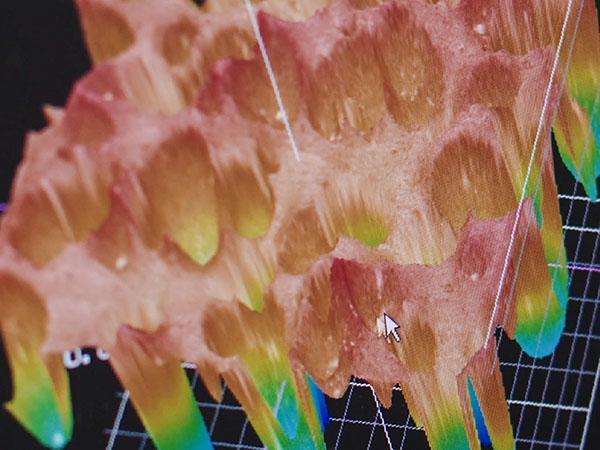

3D microscopic analysis images. Observing the detailed state of sponge air bubbles.

Evaluating the newly developed material's physical property.

Measuring the thickness. Confirming the thickness of samples for evaluation.

Measuring the hardness. With the same thickness, confirming the hardness of the samples.

Evaluating the forces acting on the rubber with computer simulations of pimple shapes.

Recording the scene during the contact with a high-speed camera. Observing deformation of the sheet and sponge.

Test Play

Both blades and rubbers undergo test play by contracted players and many others. In addition to numerical data obtained from measurements, we also value the feedback related to players' touch and feeling from test play to evaluate the equipment's performance from various perspectives. Through this repeated research and development cycle, Butterfly's blades and rubbers are created.

Producing multiple prototype blades and rubbers for comparative verification.

Feedback from player's test play, not only machine measurements, the voice from players is also important.

Using high-speed cameras to measure ball speed, spin, and swing speed.

Using a high-speed camera to observe the rotation of a ball, comparing perception with verified data.

Utilizing Butterfly's technical expertise, we research, develop, and manufacture equipment with confidence, delivering it to numerous players. This is Butterfly's approach to manufacturing. Next, we'll look at the actual manufacturing processes for producing blades and rubbers.